In the ever-evolving world of manufacturing and product identification, precision, durability, and speed are key elements that define success. With the growing demand for high-quality, customizable products, businesses need efficient solutions to meet these demands. This is where lumitool lasermarking technology comes into play. In this guest post, we will explore the advantages of Lumitool Laser Marking, how it enhances production capabilities, and why it’s a game changer for industries such as automotive, electronics, medical, and more.

What is Lumitool Laser Marking?

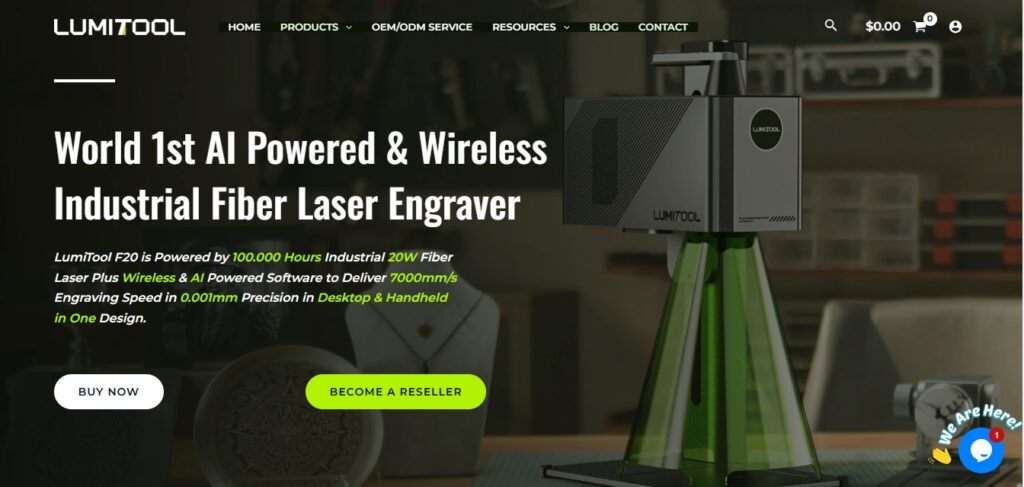

Lumitool Laser Marking refers to the use of advanced laser technology to etch, engrave, or mark designs, logos, barcodes, and text onto a variety of materials with extreme precision. This process involves using a concentrated laser beam to either melt or vaporize the surface of the material, creating permanent markings. Unlike traditional marking methods such as ink printing or mechanical engraving, laser marking provides unmatched accuracy and durability without physical contact with the material.

Lumitool specializes in creating top-tier laser marking solutions designed to improve efficiency, enhance product customization, and ensure high-quality results. Whether you’re working with metals, plastics, ceramics, or other materials, Lumitool laser marking offers the flexibility and precision required for a wide range of applications.

Key Benefits of Lumitool Laser Marking

1. Unmatched Precision

One of the most significant advantages of Lumitool laser marking is its precision. The laser beam is focused to a fine point, allowing for the marking of intricate designs, logos, serial numbers, and barcodes with incredible detail. Traditional marking methods can struggle with fine details or smaller text, but laser marking allows businesses to achieve intricate engravings that are sharp and clear, even at micro scales. Whether you’re marking tiny components in electronics or adding fine patterns to jewelry, Lumitool ensures every mark is crisp and accurate.

2. Speed and Efficiency

In today’s fast-paced business environment, time is money. Lumitool laser marking offers exceptional speed compared to traditional marking methods, enabling businesses to increase throughput and meet tight deadlines. Whether you’re marking large batches of parts or custom orders, laser marking is a quick and efficient process that minimizes production time and enhances overall efficiency.

Furthermore, the Lumitool laser marking system can be easily integrated into automated production lines, enabling continuous, high-volume production with minimal intervention. This level of efficiency is essential for companies that need to meet large-scale demands without compromising on quality.

3. Durability and Permanence of Marks

Laser markings are known for their long-lasting nature. Unlike ink printing, which can fade or rub off over time, Lumitool laser markings are permanent. The laser process creates a high-contrast, durable mark that can withstand harsh conditions such as extreme temperatures, chemicals, and physical wear. For industries like aerospace, automotive, and medical devices, where traceability and durability are paramount, Lumitool laser marking ensures that every mark is built to last.

Marks made with Lumitool are deeply etched into the material, providing a level of permanence that ensures the markings stay visible and legible throughout the product’s lifecycle, even in the most demanding environments.

4. Versatility Across Materials

Another standout feature of Lumitool laser marking is its versatility. The technology can mark a wide range of materials, including metals (stainless steel, aluminum, titanium), plastics, glass, ceramics, and more. Whether you’re working with industrial parts, consumer goods, or medical devices, laser marking can be customized to suit the specific requirements of the material and application.

For example, Lumitool laser marking is highly effective for marking anodized aluminum, which is commonly used in the aerospace industry. It can also engrave directly onto stainless steel and other metals used in medical devices, creating highly legible, precise markings that are essential for regulatory compliance.

5. Cost-Effective and Low Maintenance

When compared to traditional marking methods, laser marking is a highly cost-effective solution. The Lumitool laser marking system has minimal consumable costs since it does not require inks or external supplies like labels or printing plates. In addition, the lack of physical contact between the laser and the material reduces wear and tear, leading to fewer mechanical failures and lower maintenance costs.

Unlike mechanical engraving, which can involve frequent tool replacements, Lumitool laser marking uses a laser beam that doesn’t degrade over time, ensuring that the system runs efficiently for longer periods. This low-maintenance feature makes it an attractive investment for businesses looking to minimize operational costs.

6. Eco-Friendly Process

Sustainability is increasingly becoming a priority for businesses and consumers alike. Traditional marking methods often involve the use of inks, solvents, and other chemicals that can be harmful to the environment. Lumitool laser marking offers a more eco-friendly solution by eliminating the need for chemicals and reducing waste. The laser marking process uses only energy and light, making it a cleaner, more sustainable alternative to traditional methods.

By adopting laser marking technology, companies can reduce their environmental footprint and align with sustainable practices, contributing to a greener future.

Applications of Lumitool Laser Marking

Lumitool laser marking is used across a variety of industries, thanks to its versatility, precision, and reliability. Here are some common applications:

- Product Identification and Branding: Companies can use Lumitool laser marking to engrave logos, brand names, and serial numbers onto products, ensuring clear and permanent identification.

- Automotive Parts Marking: The automotive industry relies on laser marking for engraving parts with serial numbers, barcodes, and other essential markings. Lumitool ensures that these markings are durable and resistant to wear and tear.

- Medical Device Marking: For industries like medical devices, where traceability is critical, laser marking is used to engrave critical information such as lot numbers, expiration dates, and serial numbers.

- Aerospace: Aerospace components often require high-precision markings for tracking and regulatory purposes. Lumitool laser marking is ideal for engraving flight-critical parts.

- Consumer Goods: Laser marking is used in the personalization of products like jewelry, electronics, and custom gifts, offering businesses the ability to provide tailored, high-quality products.

- Electronics: The Lumitool laser marking system is perfect for marking delicate electronic components with microtext, logos, or part numbers that are readable under magnification.

Why Choose Lumitool Laser Marking?

The Lumitool Laser Marking system stands out for its cutting-edge technology, offering businesses the precision, speed, and durability they need to stay ahead in a competitive market. Whether you’re looking for a way to mark metal parts for industrial use, personalize consumer products, or enhance your branding, Lumitool laser marking offers the flexibility and quality required for a wide range of applications.

Moreover, with Lumitool’s commitment to customer satisfaction and top-tier support, businesses can rest assured knowing they are backed by an expert team ready to assist with any technical needs or custom solutions.

Conclusion

As industries continue to demand greater precision, speed, and customization, Lumitool laser marking provides a powerful solution to meet these challenges. Its precision, versatility, and low-maintenance benefits make it an ideal choice for businesses across sectors such as manufacturing, automotive, electronics, and medical devices. Whether you’re looking to enhance your product identification, personalize your offerings, or ensure compliance with industry standards, Lumitool offers the high-quality, efficient solution you need.